The Ultimate Guide To Mapes Insulated Panels

Table of ContentsIn Fill Panels Fundamentals ExplainedIn Fill Panels for DummiesLittle Known Facts About Infill Panel.What Does Infill Panel Wall Insulated Do?

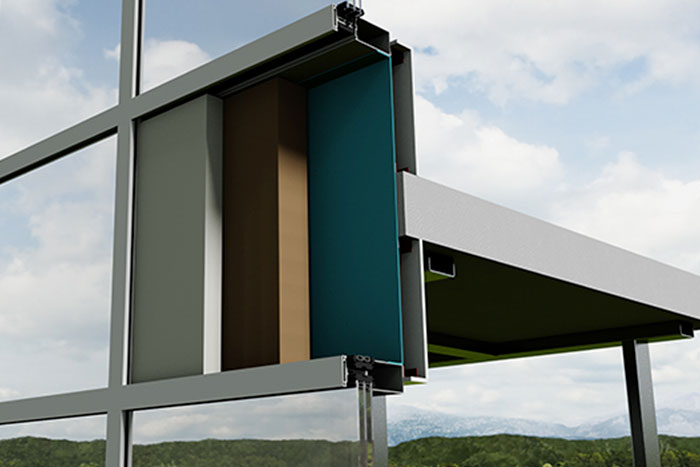

The steel sheet ought to go to least two inches behind the glass and may be painted or created to create an appearance, yet reflective surfaces add the most aesthetic deepness to the wall surface. Insulation should also be set up behind the darkness box if interior finishes prevent area air from contacting this area.Shadow boxes offer a range of difficulties connected to airing vent the cavity behind the glass, that can allow dirt on surfaces tough to tidy, or securing the tooth cavity as well as risking extreme warm accumulation. Either way, the tooth cavity might be at temperature levels substantially above or listed below interior conditions with only thermally conductive light weight aluminum in between them.

Cautious outlining can supply an approach to thermally isolate the cavity from the interior. An interior back pan behind the insulation is desirable also, to prevent condensation on the steel shadow box from the interior. Curtain wall surface systems have to transfer back to floor structure or intermediate mounting both their very own dead lots plus any live tons, which consist mainly of positive as well as negative wind loads but may likewise consist of a snow lots related to big horizontal locations, seismic lots, upkeep tons and others.

For that reason the connections to anchor the drape wall surface have to be created to permit differential motion while withstanding the loads used. In stick-framed light weight aluminum drape wall surface, vertical mullions frequently run previous 2 floorings, with a mixed gravity/lateral support at one floor and a lateral support just at the various other. The splice between the vertical mullions will likewise be created to allow upright activity while supplying lateral resistance.

Note that this activity somewhat distorts the anchors at the upright mullions. Private devices of glass should fit the activity of the bordering aluminum framework by sliding along glazing gaskets, misshaping the gaskets or a mix of both - glass infill panels. The activity of the glass within the framework and also the activity required in the supports have a tendency to generate additional stress and anxieties into a stick framed system.

All about Mapes Insulated Panels

Due to the fact that these systems are regularly custom designed, the amount of activity to be suited can be thoroughly crafted into the system. Anchoring of unitized curtain wall surface usually consists of an exclusive setting up with three-way dimensional adjustability. The supports take place at each set of vertical mullions along the edge of piece or spandrel beam of light.

The stack joint is created to resist side tons while both flooring supports resist gravity and also side tons. Among both floor anchors will certainly allow motion in aircraft with the unitized system. Fire safing as well as smoke seal at spaces between the floor slab-edge as well as the back of the drape wall are necessary check this site out to compartmentalize in between floors and also reduce the flow of fire and also burning gases in between floors.

Laboratory-tested fire rated assemblies may be required in unsprinklered buildings by some codes as Boundary Fire Control Solutions when the flooring settings up are needed to be fire-resistance ranked. The scores of the Perimeter Fire Control System have to amount to or higher than the flooring rating. These systems offer self-confidence that the materials used for perimeter control continue to be in position for the specified duration of the required ranking in a fire event.

Knock-out panels are usually totally toughened up glass to permit full fracturing of the panel into tiny items and also reasonably risk-free removal from the opening. Knock-out panels are identified by a non-removable reflective dot (typically two inches in size) located in the lower edge of the glass as well as visible from the ground by the fire division.

Describe the Source Page on Considerations for Building Style in Cold Climates. The drape wall need to be made for availability for upkeep. Low-rise buildings can usually be accessed from the ground utilizing devices with expressed arms. For high construction the structure should be made for swing phase accessibility for home window cleansing, general maintenance, and also repair, like glass substitute.

Getting The Glazing Infill Panels To Work

Drape wall leak, both air as use this link well as water, can add to IAQ troubles by supplying fluid water and condensation moisture for mold and mildew development. This leakage can frequently stay hidden within the wall surface system and also not come to be apparent up until hidden wall parts experience considerable deterioration and also mold growth, requiring expensive repair work. Typical drape wall surface toughness troubles include the following: (see Polishing).

from drape wall movements (thermal, architectural), prolonged direct exposure to water (great water drainage functions lower this risk), heat/sun/UV deterioration (age). Repairs (if viable) require considerable disassembly of curtain wall. If repair of internal seals is not physically feasible or not financially practical, installment of outside surface wet securing in all glazing and framework joints is often carried out.

Repair services glass glazing bead call for outside accessibility. Aluminum structures are inherently corrosion resistant in many settings if anodized and also appropriately secured or repainted with baked-on fluoropolymer paint. Aluminum frameworks go through damage of the finish and also corrosion of aluminum in severe (industrial, coastal) environments as well as galvanic deterioration from contact with different metals.

Drape wall surfaces as well as perimeter sealants call for maintenance to maximize the service life of the curtain walls. Boundary sealants, correctly developed as well as mounted, have a typical service life of 10 to 15 years although violations are most likely from day one. Removal and replacement of boundary sealers needs careful surface area preparation and proper detailing.

Manufacturing facility applied fluoropolymer thermoset coverings have great resistance to environmental destruction as well as require just periodic cleansing. Recoating with an air-dry fluoropolymer covering is possible however requires unique surface area prep work and also is not as resilient as the baked-on initial covering - mesh infill panels. Anodized light weight aluminum frames can not be "re-anodized" in location, but can be cleaned up and safeguarded by proprietary clear coverings to improve appearance and sturdiness.

The Ultimate Guide To Mapes Insulated Panels

The very best strategy for sustainability of curtain wall surfaces is to employ good design techniques to guarantee the toughness (optimum life span) of the installment as well as to utilize systems that have a good thermal break and high R-value (worths as high as R-7 are feasible with triple-glazed systems). Also, the use of low-e and also spectrally discerning glass finishes can significantly lower energy tons as well as improve convenience close to the wall surface.